PECVD

Silicon oxide film has been used widely in various industries due to its excellent performance on insulation, high light transmission rate and feasibility for different process. Most of the time, silicon oxide can not only be used as the passivation layer to protect the metal or Si surface in semiconductor process but also the interlayer of LED encapsulation to prevent moisture and sulfur-contained air from degrading the LED brightness gradually.

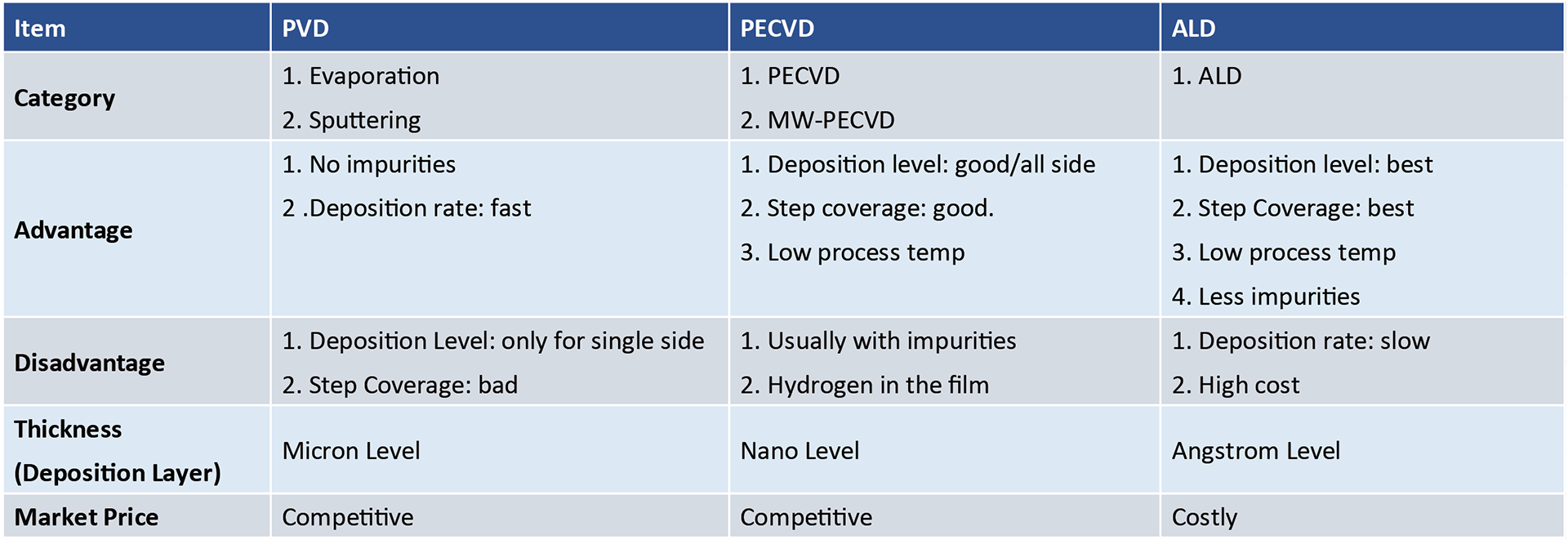

There are various methods available for depositing silicon oxide film, with PVD, PECVD, and ALD being the most commonly used techniques in industries.

Comprehensively speaking, while considering both deposition quality and cost, PECVD ( Plasma Enhanced Chemical Vapor Deposition) can be a favorable option. PECVD is a type of CVD process using plasma to enhance the chemical reactions happening during deposition. PECVD can deposit thin film at low temperature and also performs well in step coverage.

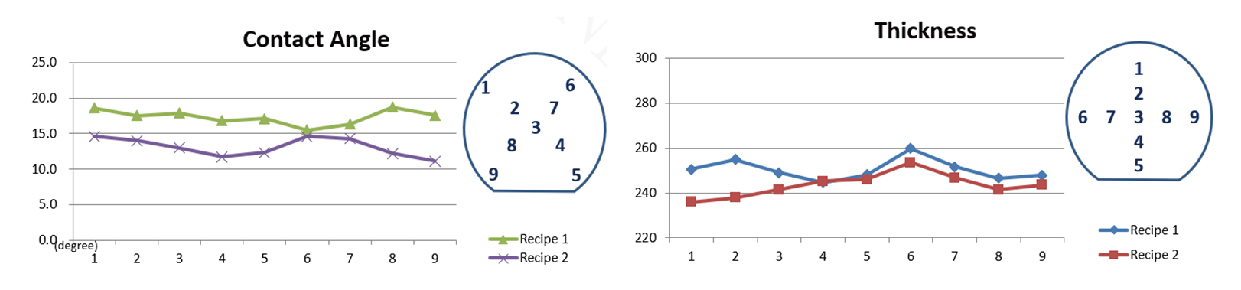

E&R’s PECVD system can deposit highly hydrophilic Silicon film at high rate and controllable film hardness, which also perform well in uniformity. Such difference hardness deposition is able to highly enhance the film adhesion and moisture resistance effect.

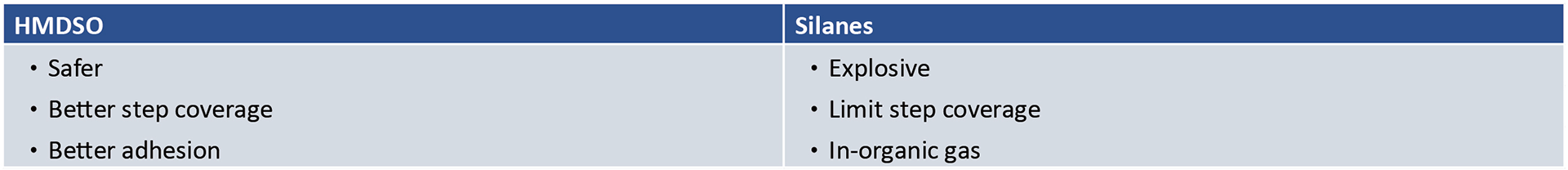

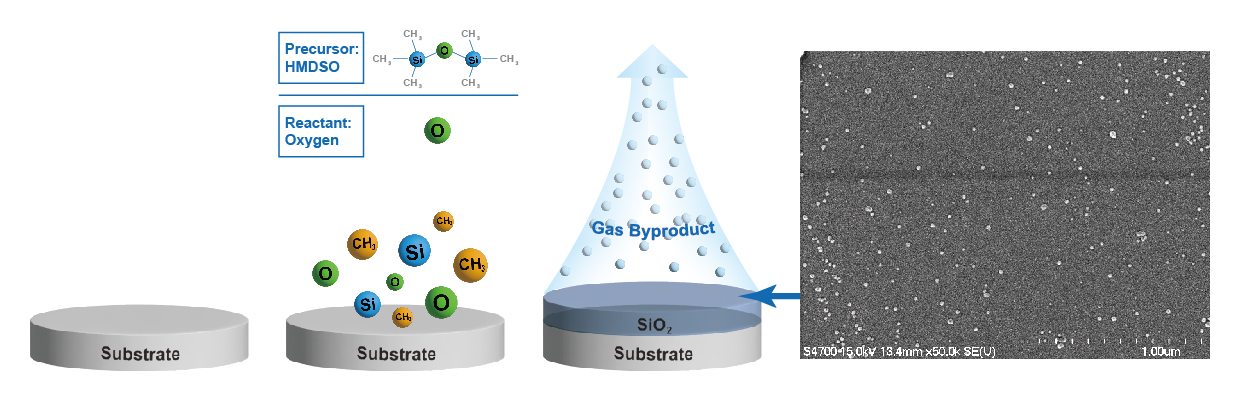

E&R has chosen HMDSO (O[Si(CH₃)₃]₂) as the precursor for the PECVD system, taking into account both safety and quality aspects. Compared to silanes and TEOS, HMDSO is considered a safer option due to its low toxicity and low flammability. Besides, HMDSO can also lead to better adhesion and step coverage of deposited films