Backend Process Solution

E&R Company is a leading provider of back end process solutions, specializing in advanced laser and plasma technology. Our innovative solutions are designed to enhance productivity and efficiency in various industries. With a commitment to excellence and cutting-edge technology, we deliver superior performance and reliability to meet the evolving needs of our clients.

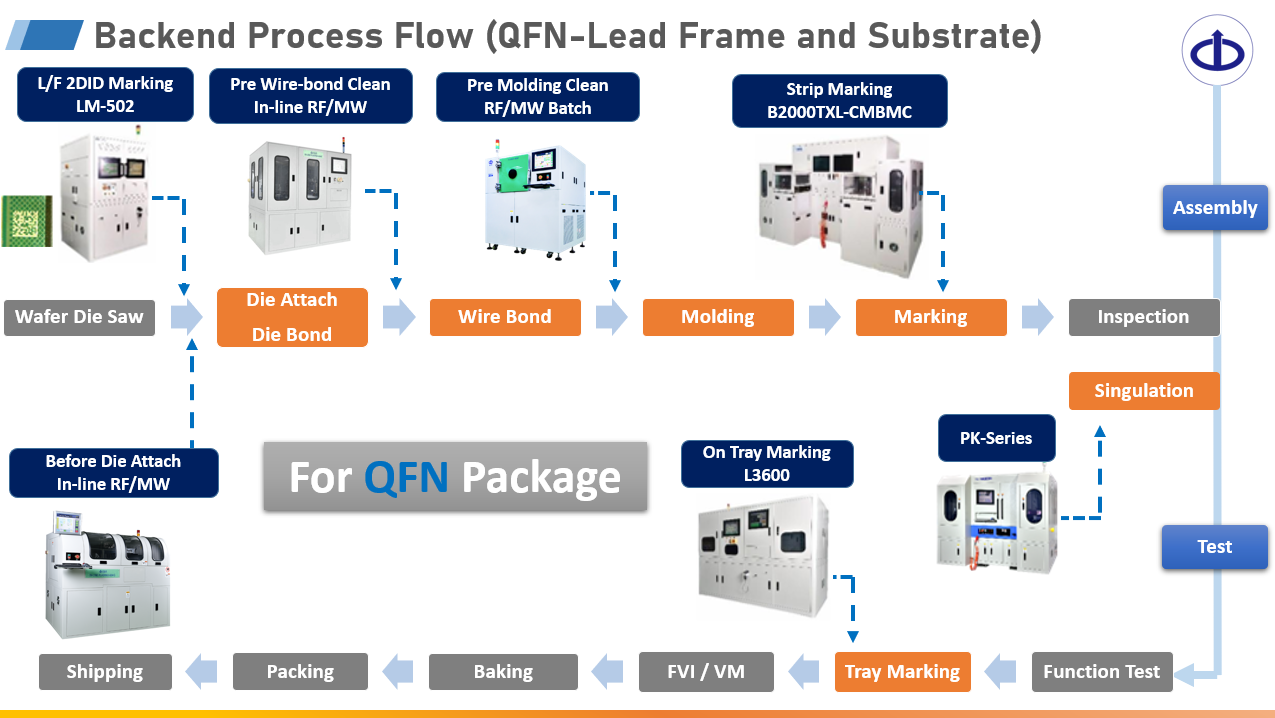

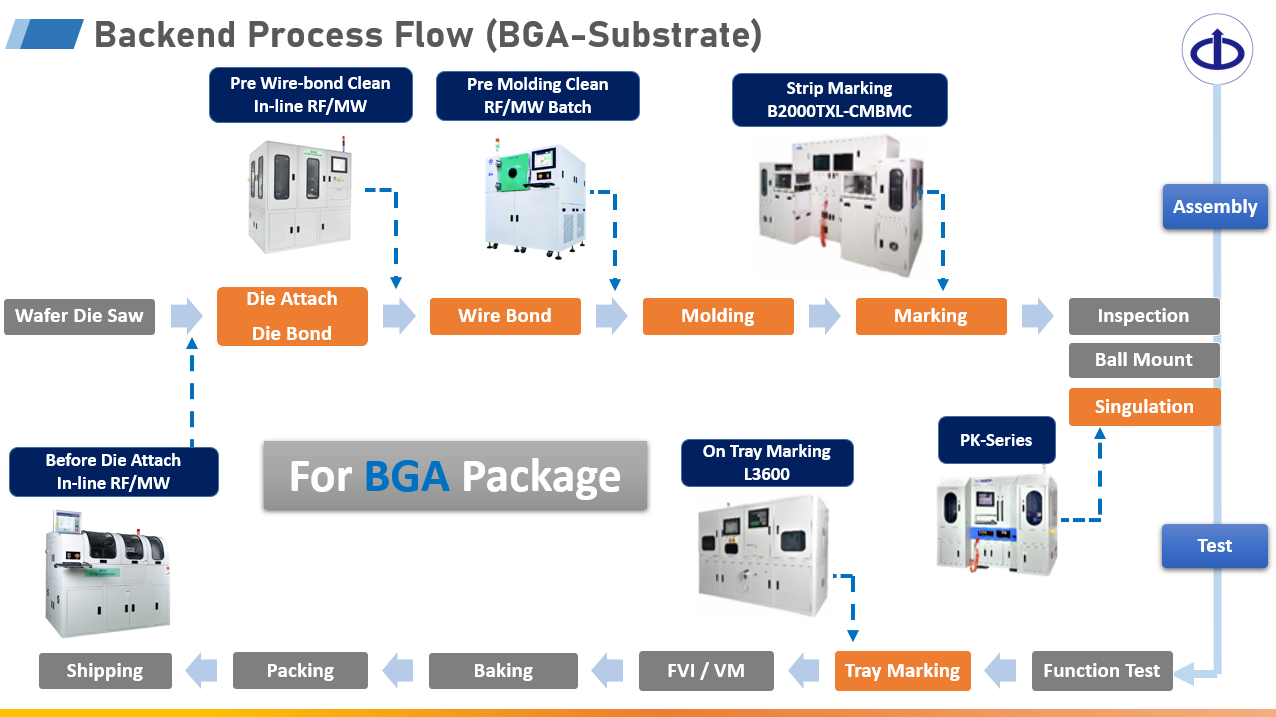

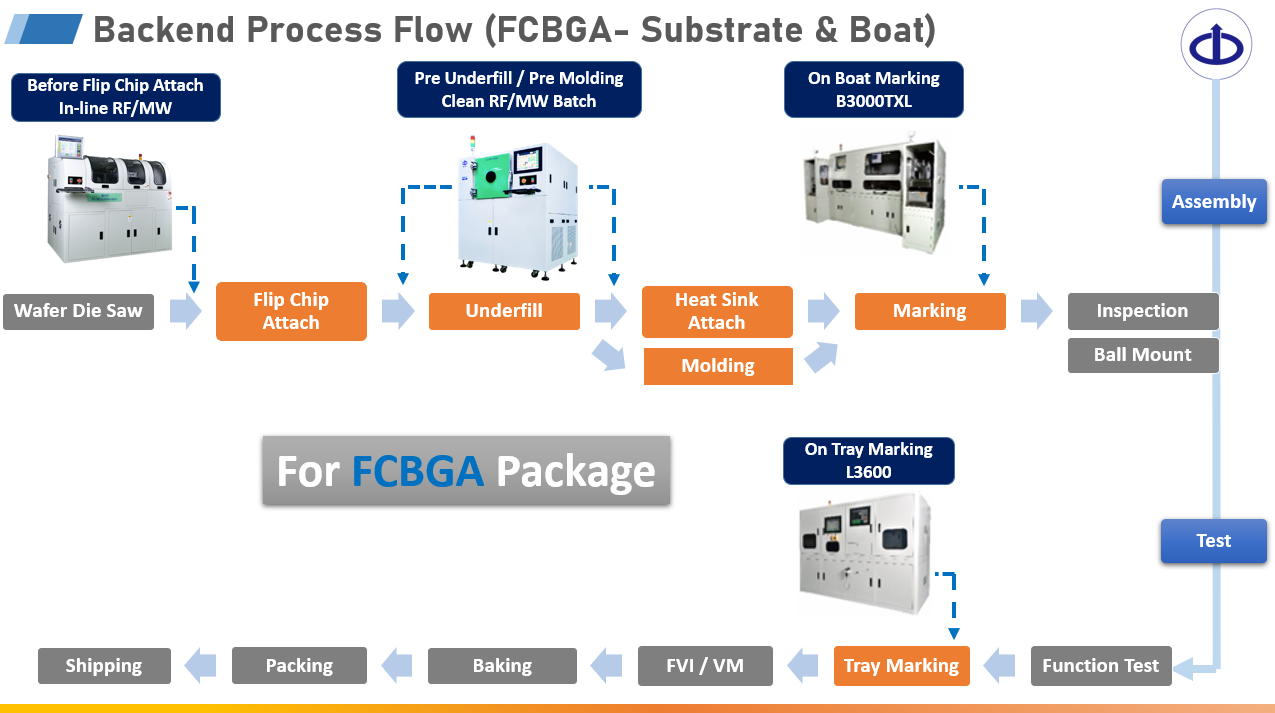

The semiconductor back end process flow typically includes several key stages:

1.Wafer Sawing:

The silicon wafers, on which multiple semiconductor devices are fabricated, are cut into individual chips or die.

2.Die Attach:

Each die is picked and attached to a substrate or lead frame using a bonding material (e.g., adhesive or solder).

3.Wire Bonding:

Thin wires are connected from the die to the substrate or lead frame to establish electrical connections.

4.Molding:

The assembly is encapsulated in plastic or ceramic to protect the die and wire bonds from mechanical damage and environmental factors.

5.Testing (Electrical and Functional):

The ICs undergo rigorous testing to verify their electrical performance and functionality. This includes tests for speed, power consumption, and functionality under various operating conditions.

6.Marking and Singulation:

Each IC is marked with identification codes or logos for traceability and then separated (singulated) into individual units.

7.Final Inspection and Quality Control:

A final inspection is conducted to ensure that all ICs meet the specified quality standards and performance criteria.

8.Packaging:

The ICs are packaged into trays, tubes, or reels for shipment to customers or assembly into electronic products.

9.Shipping:

The packaged ICs are shipped to manufacturers who integrate them into electronic devices such as smartphones, computers, or automotive systems.